RC Planes

These are my attempts of creating actual flying aircraft. I used a kit I bought on amazon for the electronics and some foam for the airframes. These aren't the best looking aircraft for two reasons, first I'm still inexperienced in RC construction (these are my first three attempts), and second the foam wasn't thick or flexible enough for RC aircraft so I had to make do. Overall I think they all performed satisfactorily, given the conditions. With regards to the pictures, the backgrounds are a bit messy because I took them right after completing them (without picking up my work station).

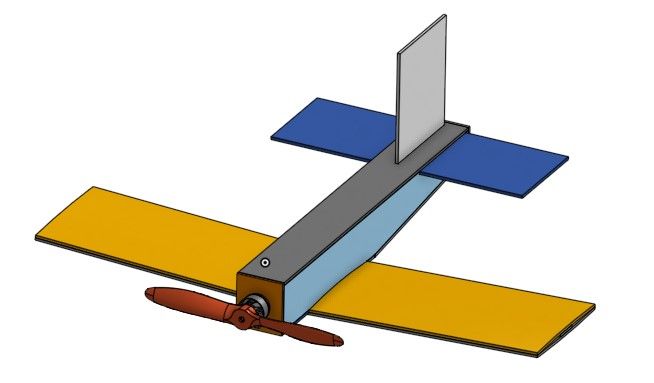

Model I

This is my first ever design and the one I had originally designed to be my one and only aircraft, which is why I started with a thorough 3D Model. However after seeing how much foam I used in the construction, I realized that I couldn't make repairs should it crash and take major damage. This prompted me to make two other smaller and simpler designs that I made extensive repairs on. I like this design a lot but with its large size comes fragility, specifically in the wings which are long and thin. The issue is I don't have enough foam to add a second layer to make it more sturdy, so it is indefinitely grounded as they say. The plane itself is about 2 feet long with a 3 foot wingspan. It has a high mounted and dihedral-ed wings to ensure stability since it is a 3-channel aircraft (thrust, elevator, rudder). Aside from the fragility, I'd say its a good design, and fragility is not an uncommon issue in the Aerospace industry. (My favorite plane in which this was an issue was Lockheed's CL-1201, a plane as tall as most buildings. This plane was so big that there was no material strong enough in existence to bear the weight.) The intention of this plane was to see if the angled-surface-wing could create enough lift to suffice for the PVC plane aforementioned. It should be able to theoretically, and there is precedent in aviation history in the Bleriot XI, an early French aircraft.

Model II

This was originally intended to be a scaled down version of the Mark I, however it brought about a major realization: a monolayer wing is too weak, which is why I haven't flown the Mark I yet. So the first enhancement I made was to add a double layer on the middle half of the wing so as to strengthen it which has worked well. After the third test flight, I switched it from a high-mounted wing to a low-mounted because the connecting joints in the high-mounted wings were too weak to support the fuselage, despite my best efforts. I also doubled up on the vertical stabilizer (in a configuration seen in other aircraft like the A10 Warthog) because in my third flight I realized that the rudder created an unexpected yaw so I tried to neutralize that.

Model III

This I designed based on the criteria of making it as simple as possible and with as little foam as possible, in order to make easy repairs. To fulfill the simplicity criteria, I made it two channel (thrust and elevons), with a simple delta wing. The fuselage itself is a simple rectangular prism with a landing gear attached. I no longer have this aircraft because I crashed it and I salvaged it for foam and electronics. The reason it crashed was completely on me, I though I had set the auto-stabilization in the training mode feature on the remote but it didn't activate. Because elevon aircraft are characteristically unstable without automatic stabilization or a skilled pilot, it crashed very quickly. Elevons are control surfaces that act as elevators and ailerons simultaneously.

Power Up 4.0 Mark I

This I designed with a V-stabilizer, for simplicity, and a simple wing. This flew, however it was very unstable and weak so I reinforced it with cardboard, but that did nothing to stabilize so I ended up moving on to the Mark II.

Power Up 4.0 Mark II

This one was built based off the last one and flew perfectly, however it had a tendency to dive like a Stuka dive bomber and not recover. I found out this was an issue with the center of lift and the fact that it was a windy day. So I fixed the issue and when the wind died down, if flew beautifully. After testing it over and over, it turned out that the dihedral put a lot of stress (due to landing) on the spar that came with the Power Up and it snapped.

Model IV

I am extraordinarily happy to say that this is my first successful model which I have absolutely no complaints about. It is very stable and decently maneuverable as well as structurally durable. I constructed this with as simple construction techniques as possible using round measurements and simple shapes. This allowed for more precise and accurate construction, ultimately being more reliable. I also used a tri-layer wing. The way this worked was that I had two 5"x12" layers with another thin piece between them that was 1"x12". The middle layer acted both as a spar and also serves to arch the other two layers when the edges are connected. This created a laminar flow airfoil like shape which was pretty thin, so it wasn't as effective as it could be but as the flights show it worked well enough. I also realized a few other things. First the fuselages caused a lot of drag in Models I and II, so I thinned it out similar to the way it was in Model III. Two, I had to do a dihedral wing because the Model III delta wing is unstable, especially for an unexperienced pilot like me. Three, I realized that measuring angles like I did in the Model I wasn't reliable hence the aforementioned construction method. Four, I realized upon reflecting on many different propeller-powered airplanes that the stabilizers are almost always positioned above the level of the wings so I applied the concept here. I honestly don't understand the physics behind it but it worked, it was a lot more stable pitch-wise. Five, I realized that the balance of an aircraft can be very easily altered by shifting electronics so I used velcro to keep everything still. Lastly, I often had trouble with reliable access to electronics so what I did was I made the top-front half of the fuselage flap up. These changes allowed for the success of the flight and the aircraft.